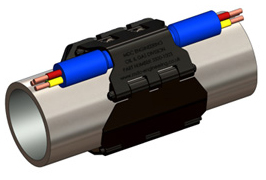

Fabricated Protector Clamps

This range of protector clamps are pressed, formed and fabricated from medium carbon sheet steel grade HR4C.

A unique design feature is a small steel cast section that forms part of the fabricated strap which enables the clamp to be tightened onto the production tubing by the use of captive bolts. All our fabricated protectors are supplied painted to suit their operational environment and coated with an anti corrosion spray on rotating hinges and joints.

The very low profile of this type of protector aids assembly into the drift and minimises the chance of ‘hang up’ when passing through the sleeves. All our clamps feature captive swivel flange bolts to enable quick assembly over the cables and onto the production tube without the risk of loss down the well A sturdy central spine shrouds the cables giving maximum protection. We manufacture protectors to suit all types of cables, control lines and flatpack combinations. Modular design for the cable retention components reduces manufacturing lead times.

Lightweight yet durable design minimises the load on well string and having one of the smallest frontal areas maximises the passage of debris between the clamp and the drift. Unlike other manufacturers who rely on tapered pins our range of protectors require no special impact tools for assembly which reduces operational costs and prevents vibration damage to any sensitive control line equipment.

Rigorous testing is undertaken on all new clamp designs to ensure our products are fit for purpose and minimise well down time.

Standard protectors are available to suit the following production tube sizes:

Standard protectors are available to suit the following production tube sizes:

- 2 3/8” (60.33mm)

- 2 7/8” (73.03mm)

- 3 1/2” (88.90mm)

- 4 1/2” (114.30mm)

- 5” (127.00mm)

- 5 1/2” (139.70mm)

- 7” (177.80mm)

Please contact us for your specific requirements.