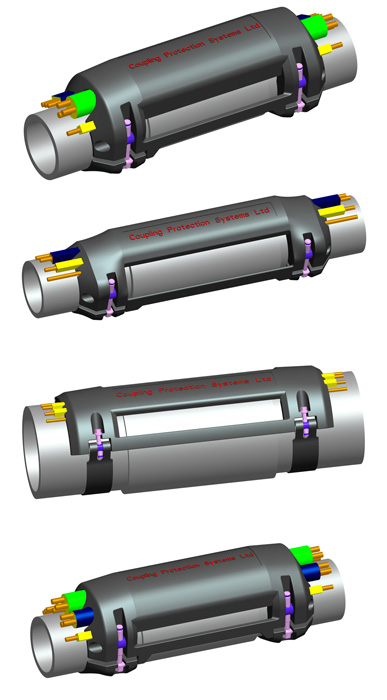

Protector Clamps

This range of coupling protector clamps are investment cast from carbon steel (ASTM Grade A216 WCB) and comply with NACE standard MR-01-75.

This range of coupling protector clamps are investment cast from carbon steel (ASTM Grade A216 WCB) and comply with NACE standard MR-01-75.

The castings are heat treated to provide a hard wearing surface yet remain ductile enough to withstand high impact loads. All clamps are supplied coated with an anti corrosion spray as per customer requirements.

Designed to incorporate streamlining at both ends aids assembly into the drift and minimises the chance of ‘hang up’ when passing through the sleeves. All our clamps feature captive swivel flange bolts to enable quick assembly over the cables and onto the production tube without the risk of loss down the well A sturdy central spine shrouds the cables giving maximum protection and side rails prevent bolt shear during end impact loading.

We manufacture protectors to suit all types of cables, control lines and flatpack combinations, applications requiring a large number of these usually require a second central spine on the opposite side to provide the necessary space and protection. For all the variations we can also supply suitable mid joint protectors.

During development all new clamp designs are subjected to rigorous testing which comprise of:-

- 15 Tonne ‘Mid Point’ spine loading test

- 20 Tonne axial loading slide resistance test

- 5 Tonne rotational loading slide resistance test

- Axial loading destruction test

Standard protectors are available to suit the following production tube sizes:

- 2 3/8” (60.33mm)

- 2 7/8” (73.03mm)

- 3 1/2” (88.90)

- 4 1/2” (114.30mm)

- 5” (127.00mm)

- 5 1/2” (139.70mm)

- 7” (177.80mm)

Please contact us for your specific requirements.